What is the production process of compound organic fertilizer NPK?

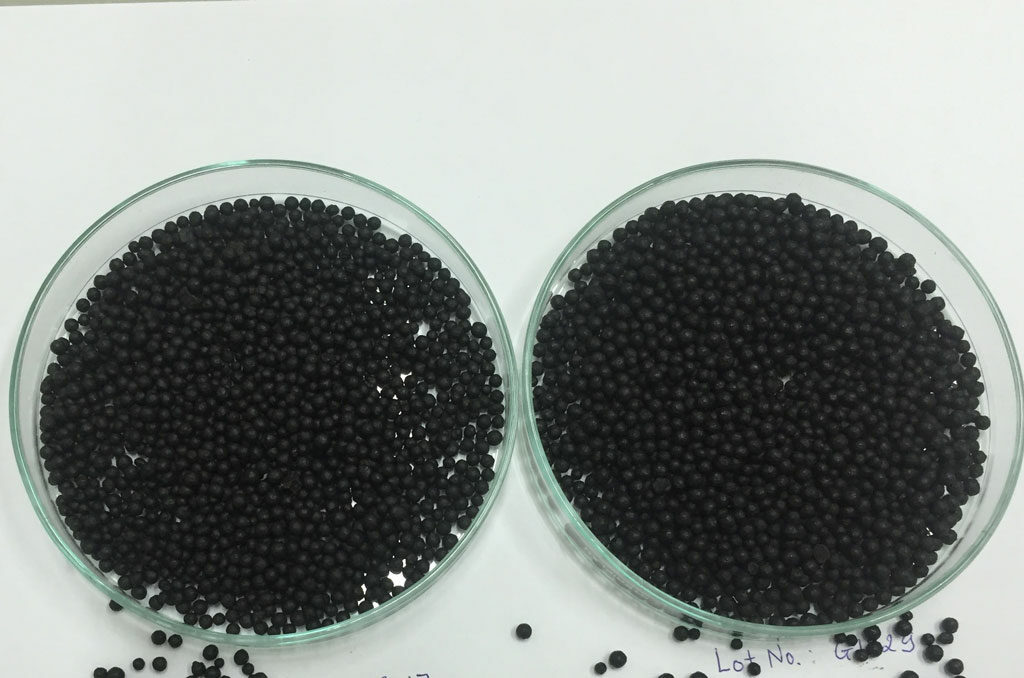

Compound organic fertilizer NPK : 8-2-4 and 11-2-4 produced by spray granulation thought advanced fermentation technology, used GA-CMS (Glutamic acid – Condensed Fermented Molasses Soluble Liquid) as a basic raw material and adding M.A.P (Monoammonium phosphate) in the production process to increase P2O5 content.

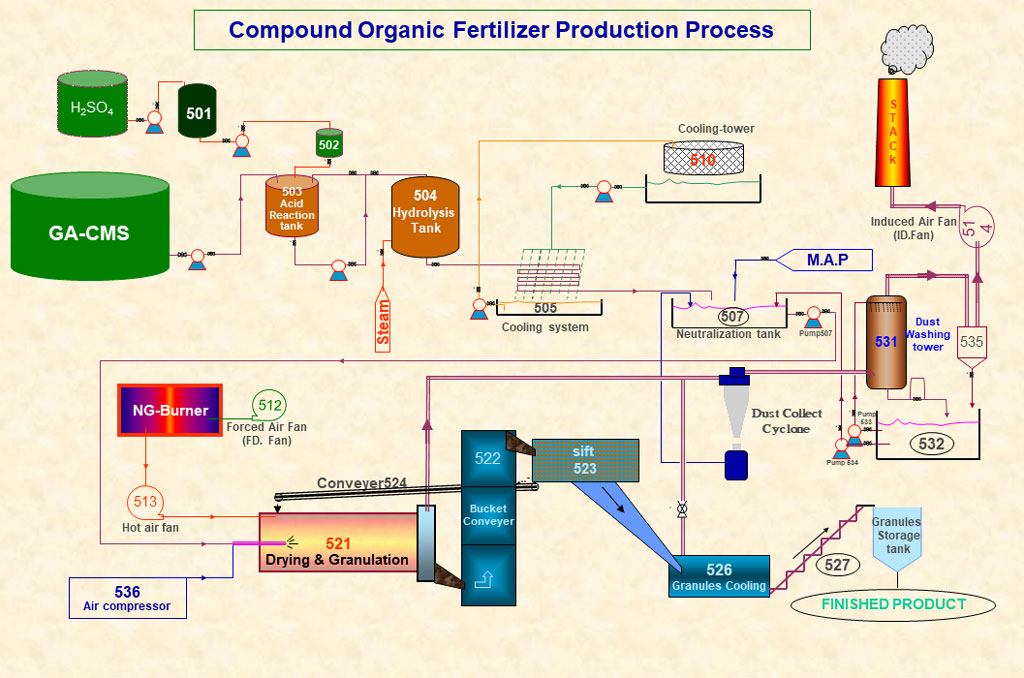

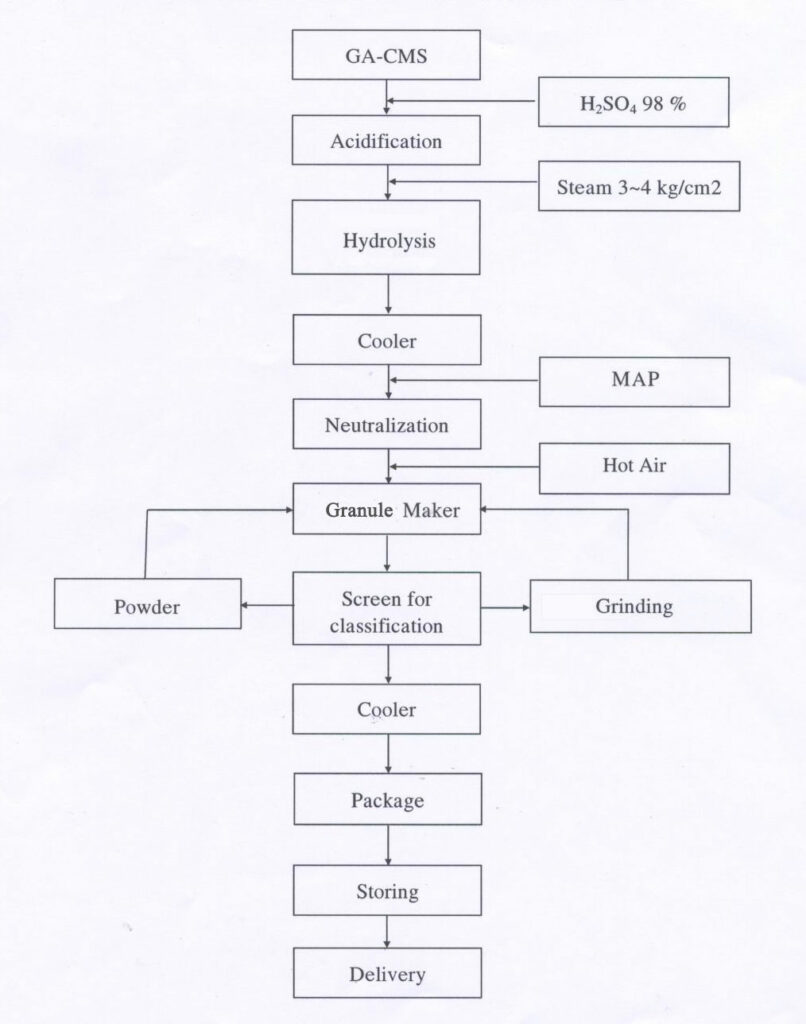

Explanation of production process of compound organic fertilizer NPK:

1st step. GA-CMS is used as a main material for making compound organic fertilizer.

2nd step. Sulfuric acid is used to hydrolyze protein existed in GA-CMS slurry into amino acid. Hydrolyzed process is also aimed at reducing the viscosity of liquid GA-CMS slurry and make it easier to form granular at the drying step. This process takes place at high temperature and steam is used as heat source.

3rd step. Hydrolyzed slurry at high temerature then cooling down is needed prior to pass to next step.

4th step. Hydrolyzed slurry of GA-CMS is neutralized with M.A.P to reach P2O5.

5th step. GA-CMS slurry is sprayed to form granular and dried by hot air at high temperature.

6th step. Sifter is used to classify particle size of granular. Also, powder and lump will be rejected at this stage and will be returned back for reprocessing.

7th step. Granular after sieving is remaining very hot and cooling is needed prior to packing.

8th step. Packed in the PE bag with PP woven bag outside and sealed to prevent it from taking up moisture during storage.

For further information, please feel free to contact us.